Chlorine is a very reactive and adaptable element with several uses in a wide range of industries. Making calcium hypochlorite is one of the main applications of chloride. A common chemical used as a disinfectant and bacteriostatic agent is calcium hypochlorite.

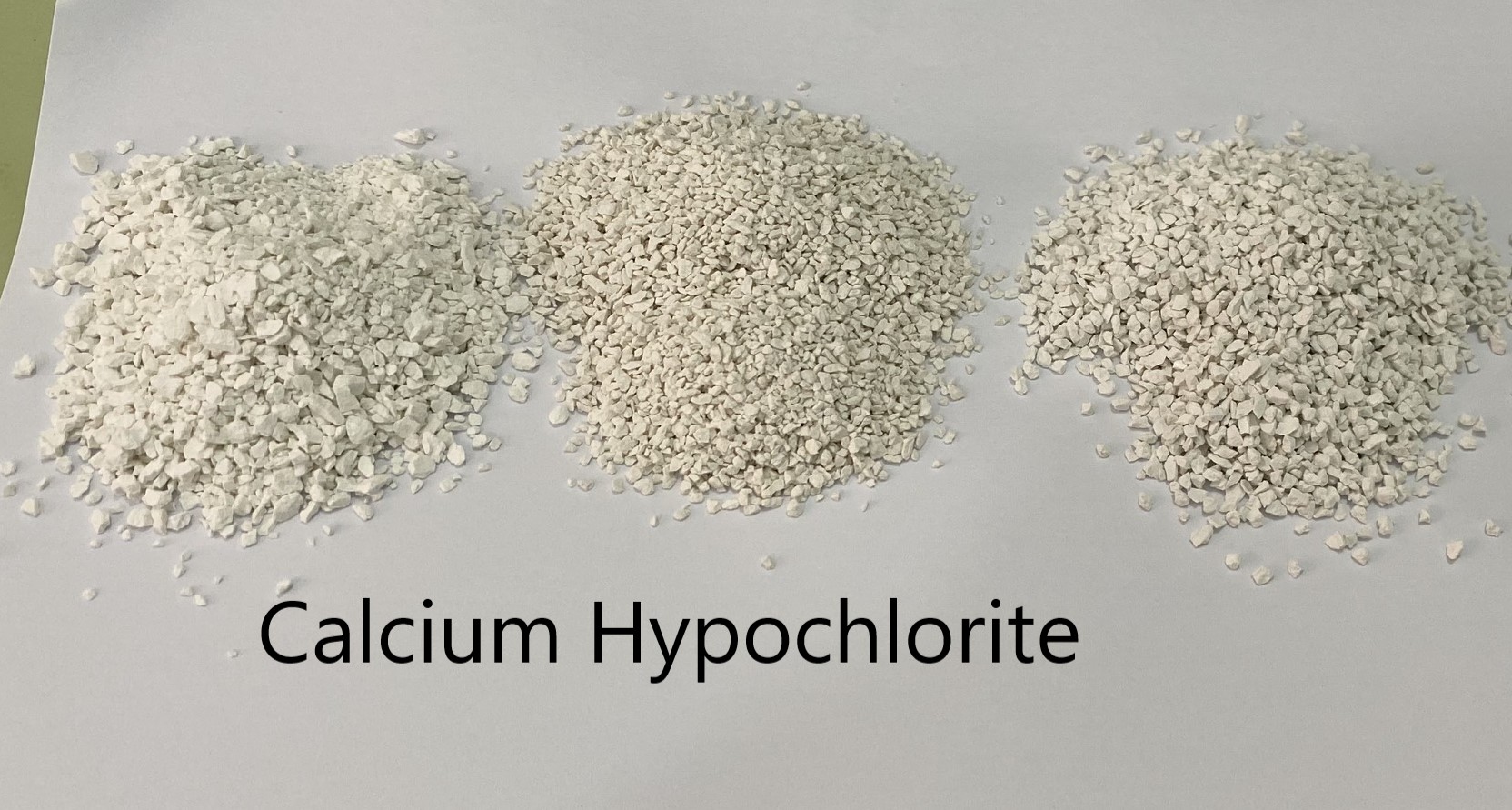

Calcium hypochlorite, which has the chemical formula Ca(ClO)2, is a white, crystalline solid. This potent oxidizing substance is used to clean swimming pools, purify water, and bleach clothing. When calcium oxide and chlorine gas combine, calcium hypochlorite is created. This process produces a lot of heat and is quite exothermic. Calcium hypochlorite synthesis is a multi-step, complicated process.

Processes used to produce calcium hypochlorite

There are multiple phases in the production of calcium hypochlorite. The preparation of calcium hydroxide is the first stage. By adding calcium oxide (quicklime) to water, calcium hydroxide is created. The equation for the very exothermic reaction between calcium oxide and water is as follows:

CaO + H2O → Ca(OH)2 + heat

The second step is the production of chlorine gas. Chlorine gas is produced by electrolysis of salt water (sodium chloride solution). The electrolysis of brine produces chlorine gas, hydrogen gas, and sodium hydroxide. The reaction equation is as follows:

2NaCl + 2H2O → 2NaOH + Cl2 + H2

The third step is the reaction between calcium hydroxide and chlorine gas. Calcium hydroxide reacts with chlorine gas to produce calcium hypochlorite and calcium chloride. The reaction equation is as follows:

Ca(OH)2 + 2Cl2 → Ca(ClO)2 + CaCl2 + 2H2O

The reaction between calcium hydroxide and chlorine gas generates a large amount of heat. The temperature of the reaction must be carefully controlled to prevent the formation of undesirable by-products.

The fourth step is to separate the calcium hypochlorite from the calcium chloride. A mixture of calcium hypochlorite and calcium chloride is treated with water to dissolve the calcium hypochlorite. Calcium chloride is insoluble in water and can be separated by filtration. It is then concentrated by evaporation and drying to give calcium hypochlorite as a white crystalline solid.

Production of calcium hypochlorite has difficulties.

The method of making calcium hypochlorite is difficult and involves several obstacles. The strong reactivity of chlorine gas is one of the main obstacles to producing calcium hypochlorite. Due to its strong reactivity, chlorine gas may react with many organic substances as well as other chemical byproducts. To avoid the development of products, calcium hypochlorite synthesis must be carefully regulated. undesirable byproducts.

The high temperature of the interaction between calcium hydroxide and chlorine gas poses another difficulty in the creation of calcium hypochlorite. Chlorine gas and calcium hydroxide combine in a highly exothermic process that produces a lot of heat. to stop the production of undesirable byproducts.

Safe manufacturing of calcium hypochlorite

Numerous safety factors must be taken into account during the manufacturing of calcium hypochlorite. Inhaling chlorine gas, which is extremely poisonous, can result in major respiratory issues. Extreme caution must be used when handling chlorine gas, and the proper safety precautions must be followed to prevent inadvertent leaking.

Chlorine gas and calcium hydroxide combine in a highly exothermic process that produces a lot of heat. To avoid overheating the reaction vessel and the creation of undesired byproducts, the reaction temperature needs to be carefully regulated.

Strong acids and bases are also required for the formation of calcium hypochlorite. A strong base is calcium hydroxide, while sodium hydroxide is produced during the electrolysis of brine. To avoid mishaps, these compounds must be handled carefully and with the necessary safety precautions